Market Trends of India Automotive Heat Exchanger Industry

This section covers the major market trends shaping the India Automotive Heat Exchanger Market according to our research experts:

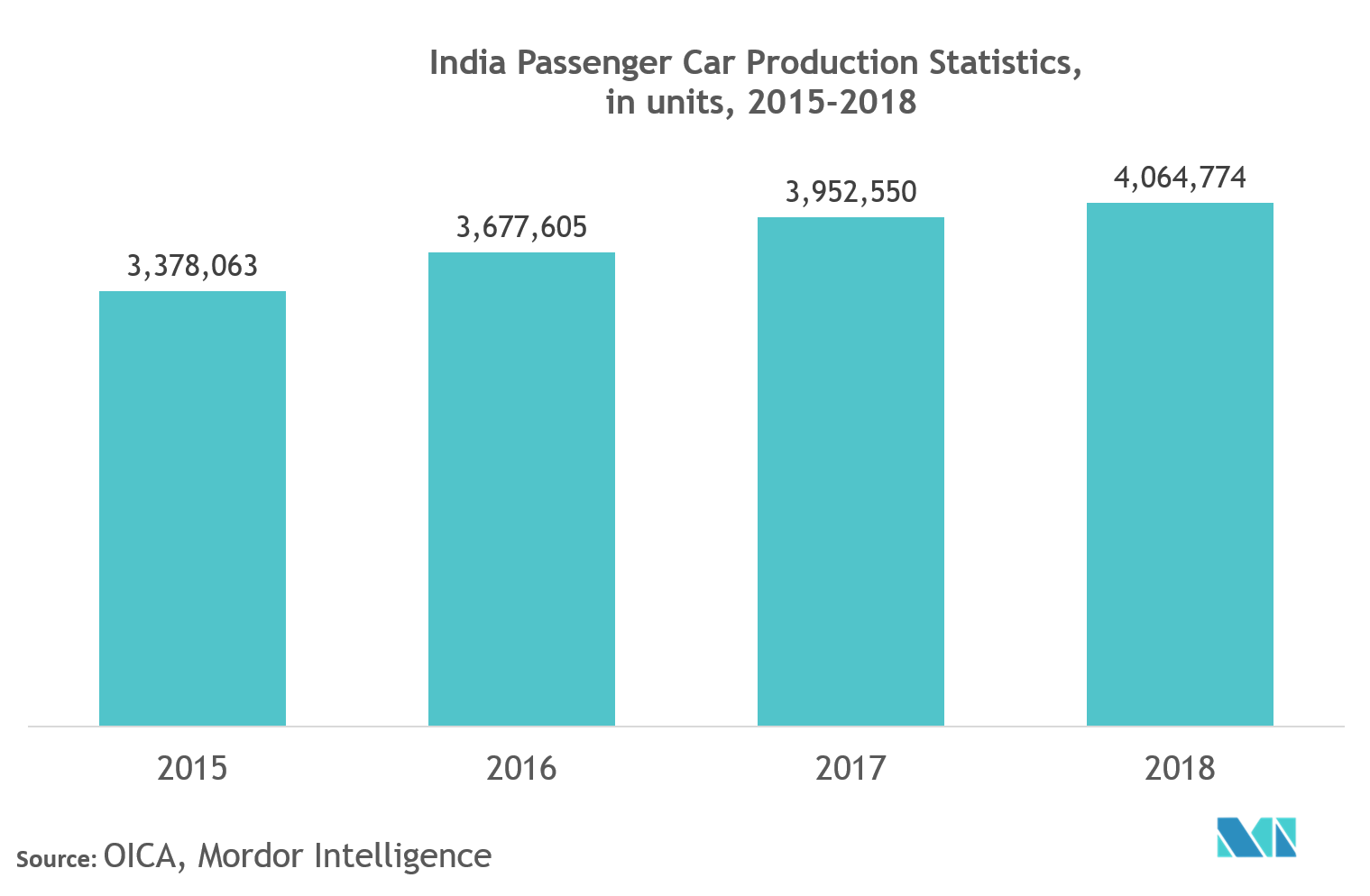

Growing Vehicle Production and Aftermarket Demand Driving the Heat Exchanger Market in the Country

The market would primarily be driven by the growth of passenger cars and LCV sales in the country. The growth expected in the overall automotive vehicle market in India would be one of the main drivers generating growth of the automatic heat exchanger market in the country.

The growth of the automotive aftermarket is one of the major factors driving the growth of the market studied. With the increase in globalization, there is increased competition among automotive heat exchanger manufacturers across the country to manufacture best-in-class products that have increased functional competency.

Additionally, there is increased competition among automotive heat exchanger vendors to gain the maximum possible share of this market. For instance, the demand for automotive radiators (which are heat exchangers used for cooling internal combustion engines) would significantly generate a demand in the aftermarket, in turn, driving the demand of automotive heat exchangers in the aftermarket segment.

Another factor which is driving the market is increase in road congestion and vehicle traffic on the Indian roads requires driving vehicles at lower gears and higher engine revolutions (rpm), leading to engines heating up at a faster rate. Such a scenario would result in overheating of the engine. An automotive heat exchanger would help to increase the engine efficiency by reducing the engine heat.

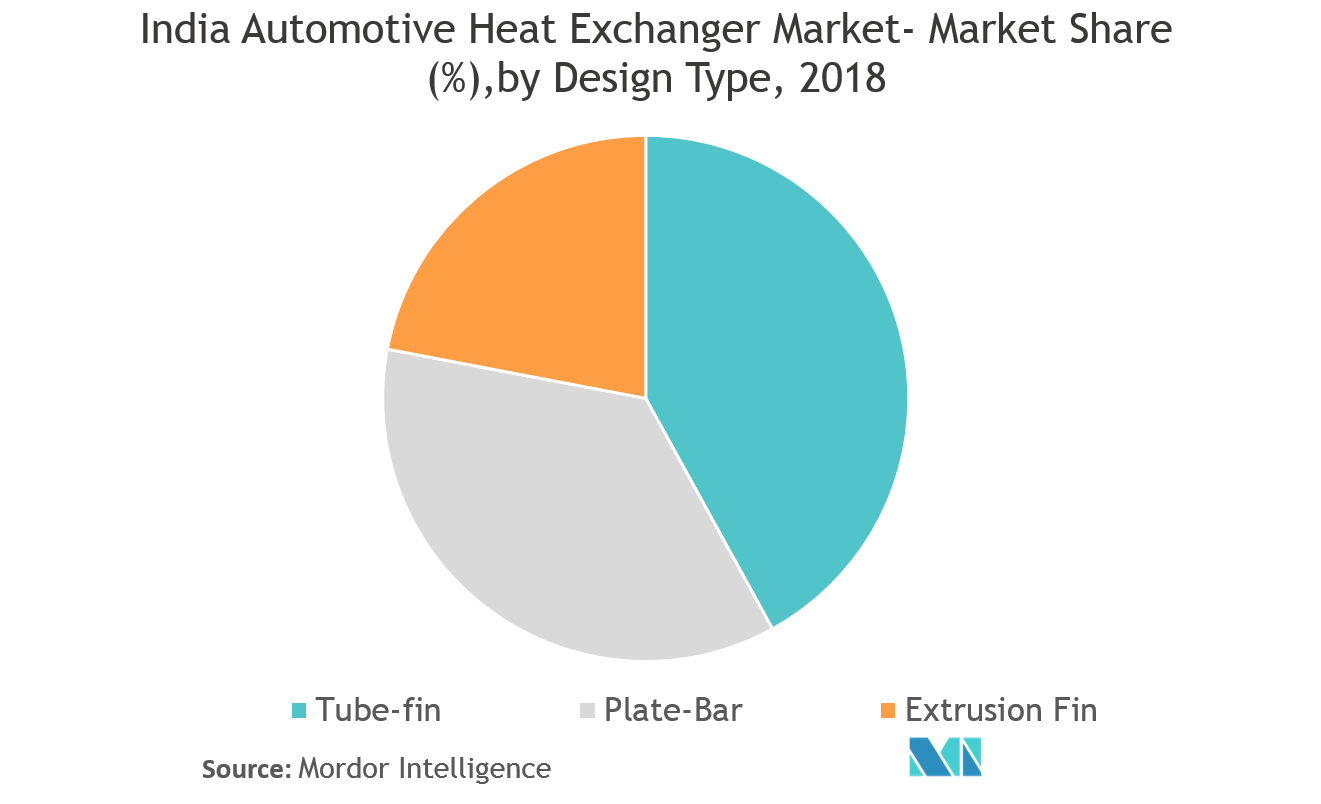

Tube-Fin Design is likely to Dominate the Automotive Heat-Exchanger Market

The tube fins are the most commonly used type of heat exchangers in automobiles. Heat exchangers, which are being used in the modern automobiles, are multiport extruded tubes that are assembled with fins for enhancing the heat exchange phenomenon.

Though brazing operation is an expensive method to manufacture a tube-fin heat exchanger, the improved performance characteristics and other benefits of reduced weight and power consumption, enhanced portability, durability, etc., are driving manufacturers to opt for this method. A radiator with better performance characteristics is expected to help keep the engine temperature low, thereby, increasing its performance efficiency

With increasing environmental concerns and the quest for cars with minimal carbon footprint, the requirement of better heat exchangers, in terms of weight, portability, and performance, has increased. This has driven the manufacturers to shift from the copper material to the lighter and better aluminum to manufacture heat exchangers.