Market Trends of US Hazardous Goods Logistics Industry

This section covers the major market trends shaping the US Hazardous Goods Logistics Market according to our research experts:

The US Oil Industry Growth

The shale oil boom in the United States is a result of an unparalleled growth in recent years, owing to the development of hydraulic fracturing and an administration that has promoted a more conducive environment for fossil fuel development. The United States is currently the largest international crude oil producer, with output estimated to exceed 12 million barrels per day in 2019 and reach 12.9 million by 2020.

With the deregulation of environment protection laws and softening of different laws restricting the access to sensitive ecosystems and relating to the emissions, the oil and gas industry has flourished, additionally, offshore drilling has also grown in the United States.

The United States already ships out more natural gas than it imports. Next year, gas production are expected to grow by another 8% to a new all-time high at 90.2 billion cubic feet per day. With the United States increasing its oil and gas exports internationally, the market is expected to observe upward growth.

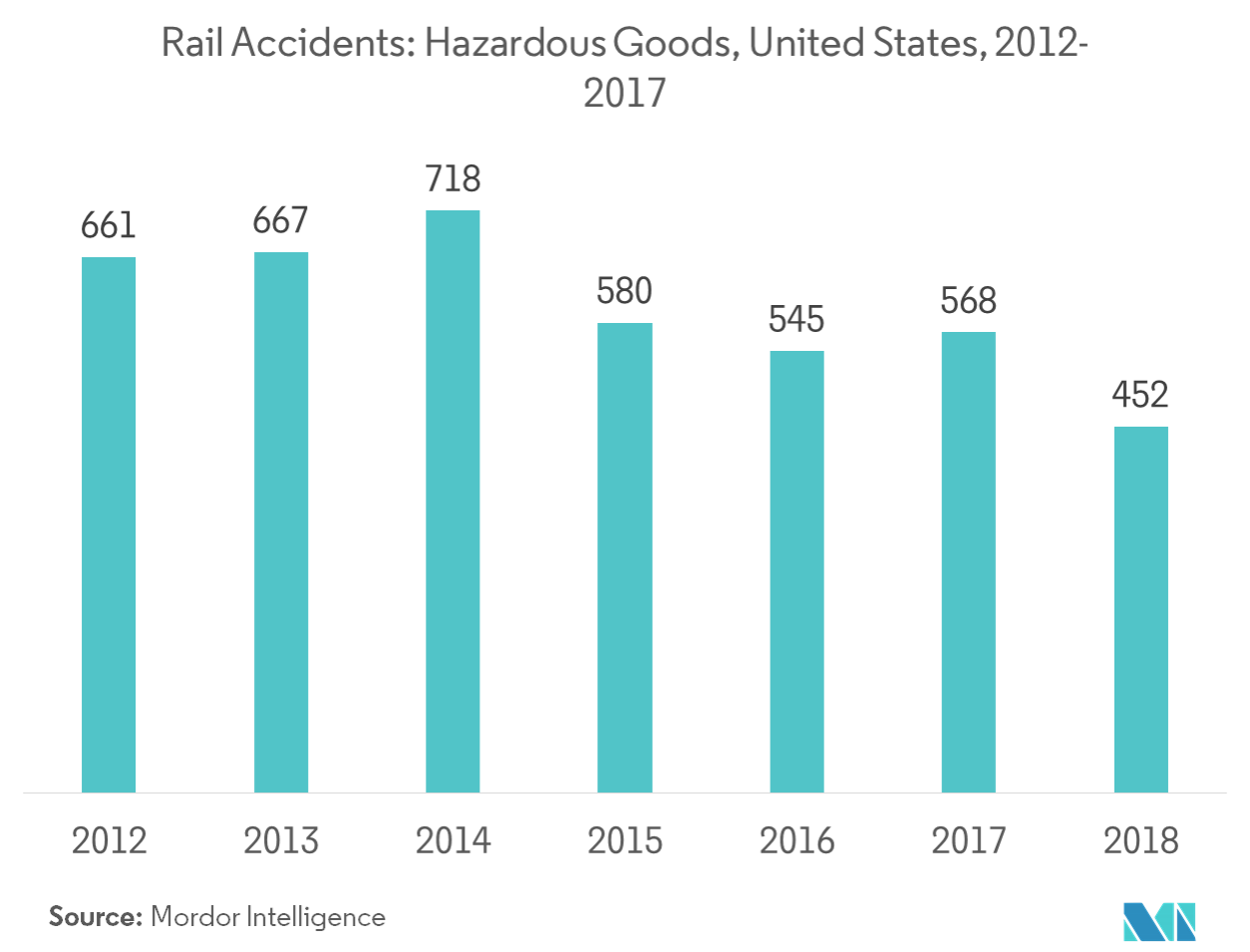

Rail is Regarded as the Safest Mode of Transport for Hazardous Goods

In 2017, more than 99.9% of rail hazardous material shipments reached the destination without a release caused by a train accident. Thus, railroads are much safer for moving hazmat compared to trucks. Additionally, railroads have approximately 10% of the hazmat accidents compared to trucks, despite roughly equal hazmat ton-mileage. Less than 1% of all derailments in 2017 accounted for cars transporting crude oil and the accident rate for rail hazardous goods transportation has dropped by 41%, since 2008.

Increasing investment in the rail network has been a significant influence on the rail network getting safer. Record levels of spending of more than USD 25 billion annually, help freight railroads make the rail network even safer. The US rail is the most capital-intensive industry, this helps the industry to achieve the safest era, with the train accident rate down by 23%, since 2008.

Implementing innovative technologies to continuously inspect track, bridges, equipment, and components may help in identifying issues and scheduling maintenance before accidents occur.

Such technologies include the use of drones to investigate inaccessible areas, ultrasound technology to detect flaws within the track, and specialized monitors mounted along the route, which identify faulty or worn railcar components as train passes.